There’s no way we’re talking about the construction industry without having to mention the most significant building material called concrete. For so many reasons concrete might be a bad idea. It has so many bad effects on the environment and climate at large.

Surprisingly there’s an engineer who has come forward with a new and innovative concept that will replace traditional concrete as the major material for building homes. This idea has the potential to revolutionize the whole construction industry.

Concrete And Its Impact On Humans

Because of concrete’s negative impact on the environment, it is often referred to as one of the most destructive materials on planet Earth. But concrete is still very important to humans, as it plays a foundational role in modern society.

Concrete serves as a primary building material for a lot of things like infrastructure, buildings, and various other building projects all over the world. However, despite its widespread use, it still gets to be called the worst man-made substance.

The Most Common Global Construction Material

Now that we’re on the same page about how common and important concrete is to our construction industry. Its function in the industry is quite substantial and far-reaching and the fact that its primary component is a carbon dioxide (CO2) distributor is alarming.

Cement is an essential ingredient in construction production and it is responsible for a very substantial portion of CO2 emissions. According to the University of Victoria, the production of cement alone accounts for about 8% of worldwide CO2 emissions.

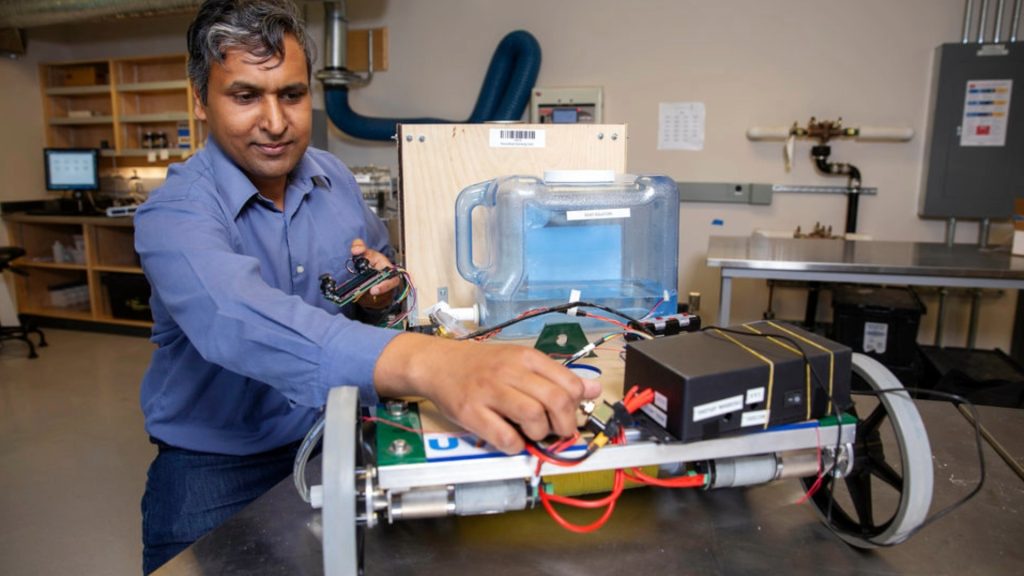

The Uvic Facility Is Working On Using Cementless Concrete For Construction

Rishi Gupta, a researcher at the Uvic Facility for Innovative Materials and Infrastructure and Monitoring is actively working on an alternative solution to using the traditional concrete for construction. The new approach he is working on might shock you.

Rishi is working on developing a cementless concrete that would do wonders. Rishi and his team plan to develop environmentally sustainable products and something that is also structurally viable.

Rishi And His Team Are Determined To Push Boundaries To Make This Work

Rishi Gupta and his are ready to do everything in their power to make this work. They are ready to advance the capabilities of concrete by exploring other binding materials as opposed to the traditional ones.

He believes that by switching to an alternative binding material they might just be able to provide an alternative that has a lower carbon footprint and something more carbon neutral.

Gupta Started His Research Ten Years Ago

Rishi had always wanted to try something new but only properly started his research on the creation of cementless concrete 10 years ago. To get the desired results, Rishi made use of materials like fly ash and some bottom ash from coal power plants.

He aimed to use this as a binding material to improve geo-polymer concrete which forms at room temperature, making it a more suitable option than the traditional Portland cement option.

The Cementless Concrete Was Made With 50% Fly Ash And 50% Bottom Ash

According to Uvic News, they revealed that to make Cementless concrete, Rishi made use of a combination of fly ash and bottom ash with a composition of 50% fly ash and 50% bottom ash that doesn’t require a high-temperature curing process.

In the aim to develop a local solution for Indiana Canada, the University of Victoria and India-Canada Impacts Centers for Excellence came together to test out these products which were used to form pavers used to make pavements and parking lots.

Choosing The Difficult And Less Traveled Route

Gupta made a statement that further explained the motive behind his innovation, he expressed the motive behind adding bottom ash together with flying ash into the production of his sustainable concrete.

Gupta did this by referring to his approach as the “difficult and less traveled route”. Gupta admits that his approach is quite challenging and less explored but he honestly didn’t mind as long as he was getting a positive response.

The Aim Is To Reduce Greenhouse Gas Emissions

Gupta added a very important fact about geopolymer concretes. He mentioned that while producing this concrete it is essential to make use of heat during the curing to help strengthen and harden it properly.

Do not forget that heat means energy and the use of heat for curing poses some kind of environmental challenges, which can in the long run result in greenhouse gas emissions which is what Gupta is trying to avoid.

Using A Sustainable Technology

Gupta goes ahead to mention that he and his team are focused on making use of sustainable technology and they are ready to show the world how it works.

Gupta goes on to tell us that the most important part of his research is the way his teams mix their geopolymer concrete. As it is quite different and requires little to no heat during the curing process.

Research On The Long-Term Effects Of Carbon Dioxide

In a statement made by Rishi, he mentioned that he and his team are also working on research about the long-term effect of storing (CO2) emissions.

Gupta and his team are trying something new like the incorporation of green fiber into CO2-sequestered concrete. The aim is to prevent cracks from forming in the concrete and also promote its healing properties.

The Perfect Development To Help Reduce Pollution

Rishi’s innovations are mind-blowing and they will be very helpful in the long run. This particular invention will be a really good way to reduce carbon pollution. Especially those that come from setting up buildings by forcefully increasing their life span.

The goal of these innovations is to make sure that there’s a reduction in the production of about 4.4 million tons of carbon dioxide that gets produced annually.

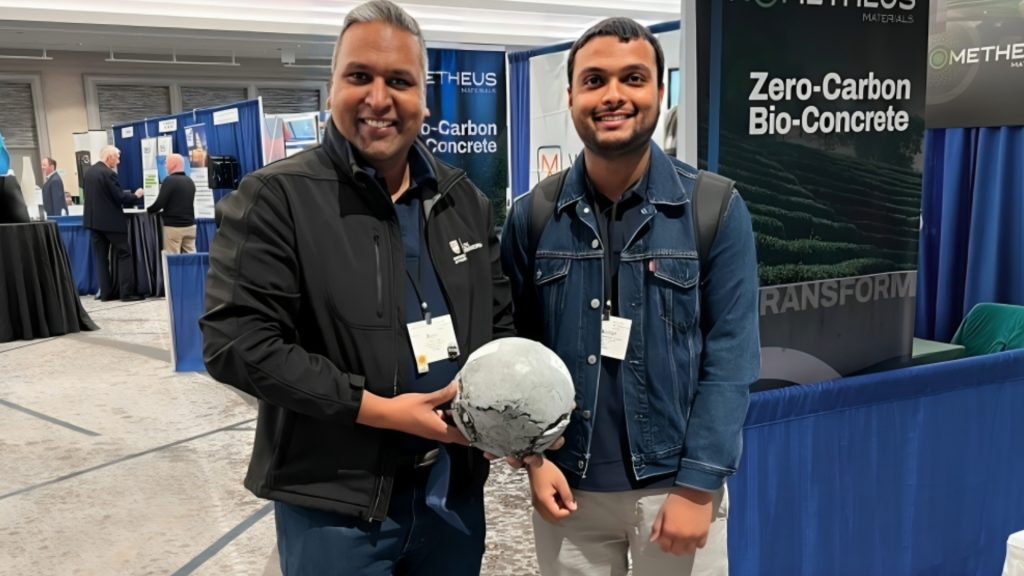

More Inventions Are Sweeping The Industry!

Here’s one thing to remember, even though Gupta’s research on CO2-sequestered concrete is innovative, several other innovations are making their way into the industry.

We have other innovations like two Startup companies working on something similar called “green concrete” and another called “sugarcrete” and these innovations could just be our way of totally escaping the use of traditional concrete.